Engine running hours are often treated as a background metric. Yet for offshore vessels, they carry direct operational and financial consequences. Maintenance frequency, fuel use, emissions, and even asset integrity all connect back to how long engines are in use, and under what conditions.

Forward-looking operators are starting to treat engine hours as a strategic lever. Not just for compliance, but for cost reduction, long-term asset care, and even competitive positioning.

From Basic Tracking to Strategic Value

Engine running hours represent how long a vessel’s engines are in operation, regardless of whether it’s in transit, DP, port standby, or field standby. This data is typically recorded daily, but on its own, it reveals little.

Where it becomes powerful is when usage is linked to vessel activity and benchmarked against efficient patterns. That’s when opportunities emerge.

With proper analysis, many vessels show high potential for improvement, especially during low-demand phases like in-port standby. Running one engine instead of two, or delaying activation during maneuvering, often makes no difference to operations but creates a measurable drop in OPEX.

Tangible Benefits for Shipowners

Reducing engine hours extends to the full lifecycle of the equipment:

- Fewer overhauls due to extended maintenance intervals

- Less lubrication oil is consumed, which carries both cost and handling advantages

- Less fouling, resulting in cleaner engine performance

- Higher average load per engine, bringing operations closer to the optimal SFOC (Specific Fuel Oil Consumption) range

- Improved vessel availability, as reduced usage lowers the chance of unexpected breakdowns

For every unnecessary hour avoided, a shipowner preserves asset value and reduces future interventions. Based on feedback from the field, each hour of engine operation avoided can save between 10 and 20 euros in maintenance alone.

Measuring Avoidable Hours

At Opsealog, we develop a dedicated module to track and analyze engine running hours across offshore fleets. The approach follows the same logic as our proven fuel optimization framework. It allows vessel managers to identify unnecessary engine use, benchmark against best practices, and reduce wear without compromising performance.

For example, suppose a vessel typically runs two main engines while alongside in port, but the best practice benchmark for that vessel class and operation is one engine. In that case, the additional hours are flagged as avoidable.

This assessment is tailored to each engine after the screening period, allowing for a fair and realistic comparison. From there, the module calculates potential savings and identifies the most impactful areas for improvement.

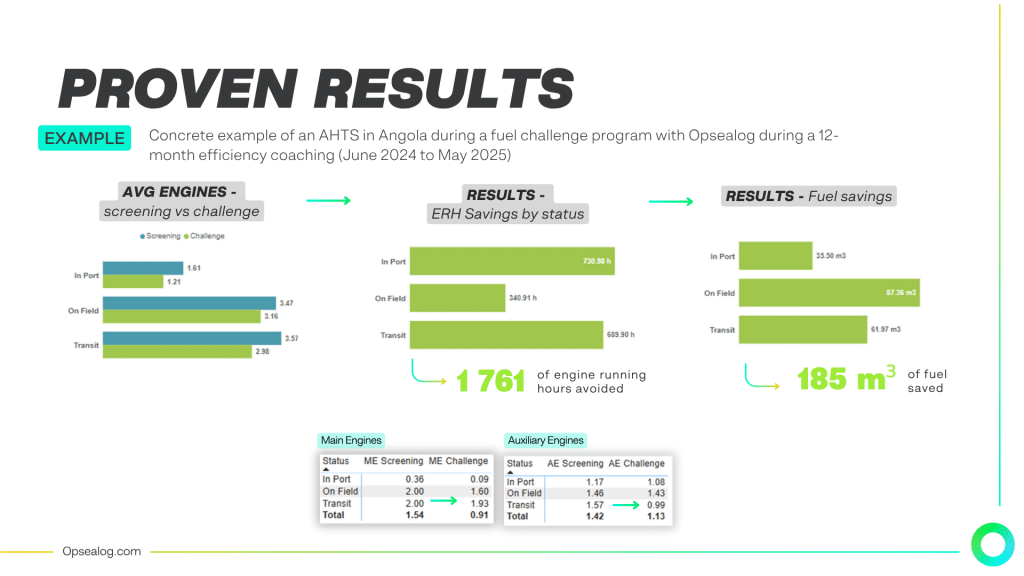

A Case in the Field: AHTS in Angola

Between June 2024 and May 2025, Opsealog worked with an AHTS vessel operating offshore Angola as part of a broader fuel efficiency program. Over the course of twelve months, the ship’s engine usage was carefully monitored, coached, and adjusted based on our insights.

- The outcomes:

1,761 hours of main engine operation avoided

185 cubic meters of fuel saved

Most of these savings came from small, consistent behavioral changes. Adjustments in port routines, DP operations, and transit strategies helped the crew reduce running hours without disrupting operations.

Curious to learn more about how our solutions can apply? Read our case study on engine utilization.

Efficiency Starts with Ownership

Regulatory pressures, such as EEXI and CII, continue to raise expectations regarding emissions and reporting. Shipowners are expected to present clear, measurable actions to improve their environmental footprint.

Reducing engine running hours offers a way to meet these goals. It does not require new hardware, major retrofits, or downtime. It relies on smarter decisions, better visibility, and the right digital partner to measure progress.

Most of the time, shipowners do not have control over operations dictated by their clients. However, they can often influence the number of engines used. Activities such as standby at sea, port stays, and transit at economical speed typically require low power and often involve excessive engine use. This presents an opportunity for the shipowner to take a proactive approach with their client and help them reduce fuel costs.

And when the vessel is off hire, these cost reductions benefit the shipowner.

Read more: Damien Bertin shares how Opsealog guides maritime leaders in their digital transformation.

Final Thought

Engine hours may seem like a simple metric, but they point to much larger opportunities. Reduced OPEX, longer engine life, improved emissions compliance, and greater vessel availability are all within reach.

At Opsealog, we’ve already developed, tested, deployed, and proven it in the field. What’s needed now is a shift in how shipowners view their data. With the right attention and mindset, engine running hours become a lever for long-term performance, rather than an additional number in a report.

Learn more about our engine hour tracking module