Offshore Support Vessels (OSVs) manage time logistics and intricate marine operations, where fuel efficiency is challenging, especially during transits. Faced with multiple challenges, optimizing the fleet’s consumption entails regularly assessing and monitoring the vessel’s behavior. In this blog, we will explore the challenges vessels face when tackling fuel efficiency during transits.

Understanding the Landscape:

The multifaceted nature of tasks and responsibilities assigned to OSVs renders their optimal design significantly more intricate compared to other transportation vessels. This complexity is further compounded by contextual factors such as field development, evolving technologies, and regulatory as well as operational constraints. Unlike many cargo ships, OSVs are relatively small, possess limited cargo capacity, and operate near their shore base, frequently undertaking short voyages. These vessels typically travel at speeds of 6 – 10 knots, slower than the typical transit speed of cargo ships. Their ability to maneuver with precision is critical for OSVs because it enables them to perform their specialized roles safely and efficiently.

Various types of transits pose unique challenges for OSVs, ranging from urgent, long, and short transits to those in deep or shallow waters, including escort duties, patrolling, … and extensive towing operations, which can also be considered transit activities. Each transit presents distinct requirements and demands, influencing the vessel’s fuel efficiency. Factors such as time constraints dictated by Estimated Time of Arrival (ETA), weather conditions, vessel characteristics and design, ongoing maintenance, and available power capacity all play crucial roles in determining operational effectiveness during transit missions.

Learn more about OSV specificities and Performance Management

Vessels navigate vast expanses, tackling unpredictable sea conditions and weather phenomena. In this blog, we focus on the main types of transits: to port, to field, and interfiled. The aim is to address a crucial question: What are the leverages to optimize fuel efficiency during transits?

The role of data:

Digital solutions are essential to leverage data analytics and unlock insights into vessel performance during vessel transits. To understand the operational profile of your vessel it is crucial to have diverse sources of data to better analyze and understand the vessel’s behavior such as benchmarking speed, engine utilization, distance sails, deadweight, weather, vessel conditions and fuel consumption, the client’s order, and more.

Data can be gathered from multiple sources; Electronic Fuel Monitoring Systems (EFMS) provide engine and sometimes navigational-related data; Automatic Identification System (AIS) provides navigational data. Most importantly, digital solutions and reporting software will provide qualitative data by integrating the Vessel’s daily reporting and help better understand the vessel’s operations. In addition to being complementary, digital solutions are considered high quality as they provide deep insights, comments, and stand-by reasons.

By harnessing data from these sources, operators can comprehensively understand their vessels’ performance metrics, enabling informed decision-making and strategic optimization of fuel consumption during transits. Yet, understanding why vessels with similar profiles have different fuel consumption can be challenging.

Key Challenges faced during transits:

When it comes to fuel efficiency, the challenges faced during transits share some similarities and differences between the two.

Remote Operations:

Many types of transits involve operating in remote or offshore environments, where access to fuel and supplies may be limited. Remote locations can pose challenges for refueling and replenishing supplies, impacting fuel efficiency. Indeed, Vessels must carry ample fuel reserves.

Weather Conditions:

Adverse weather conditions affect fuel efficiency during transits, as vessels may need to adjust speed or route to navigate safely. Rough seas or strong winds can increase fuel consumption due to higher resistance and altered sailing conditions.

Ship & Machinery Equipment:

Alongside specialized machinery equipment, the ship’s hull plays a pivotal role in transit operations. Maintaining and operating specialized equipment, including engines, propulsion systems, and auxiliary machinery, is essential for fuel optimization. Additionally, the condition of the ship’s hull directly impacts its hydrodynamics and overall efficiency during transit.

Deadweight and Deck Space Allocation:

Deadweight capacity directly influences the vessel’s ability to carry cargo, equipment, and supplies, impacting its operational flexibility and efficiency. Optimizing deadweight distribution ensures the vessel can accommodate varying cargo loads while maintaining stability and maneuverability. Furthermore, maximizing deck space facilitates loading and unloading processes during transit operations. Therefore, careful planning and management of deadweight and deck space allocation are essential to enhance the overall performance and effectiveness of OSVs during transits.

Crew Change:

While crew changes themselves may not directly impact fuel utilization, the logistical challenges associated with crew rotation may. New crew members may lead to variations in vessel handling, navigation practices, and engine utilization, impacting fuel consumption. Ensuring thorough familiarization of new crew members with vessel operations, the bridge, and fuel efficiency measures is also important.

Engine Utilization and Speed:

Optimizing engine utilization and speed is critical to optimize consumption. Indeed, maintaining consistent speeds and applying smart engine utilization in particular cases is crucial for efficient fuel utilization.

The core challenges related to fuel efficiency are specific to the operational context, and the requirements of each type of transit may lead to nuanced differences in how these challenges are addressed.

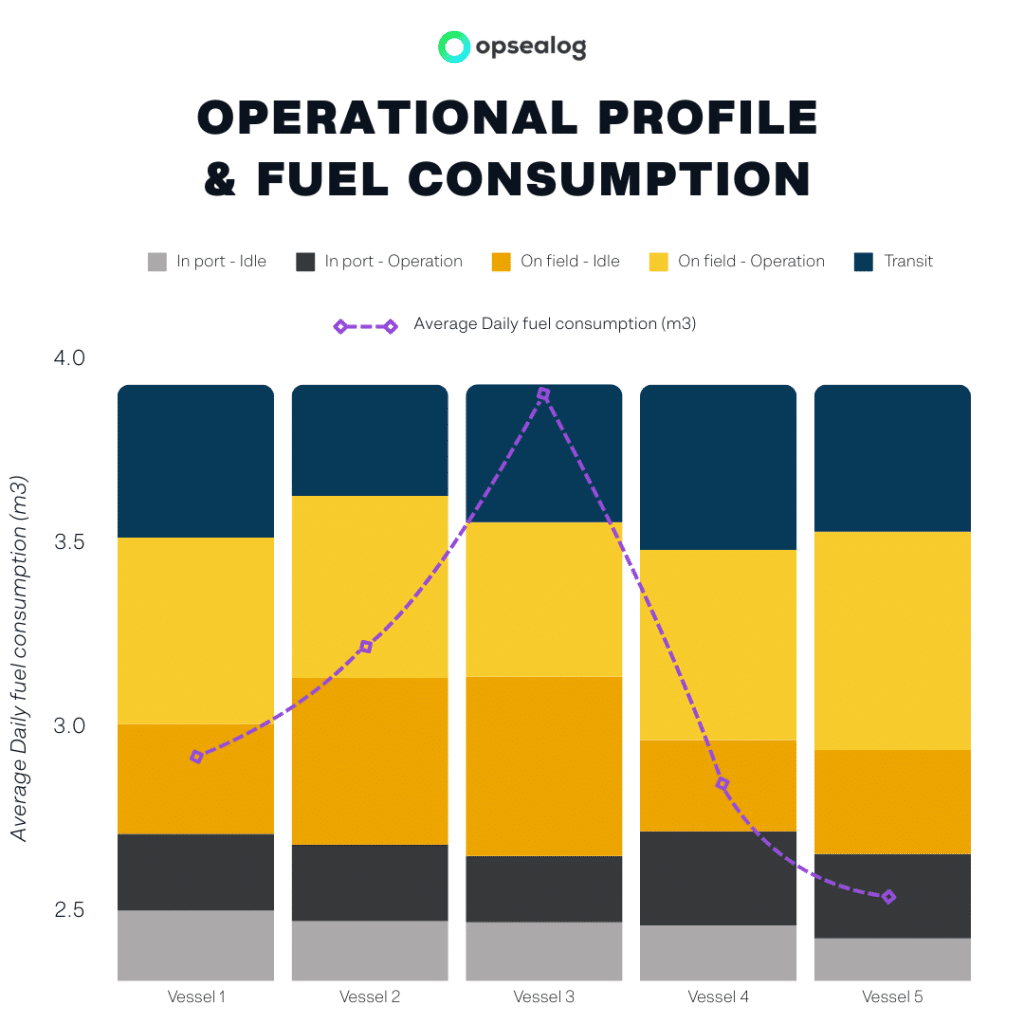

Here’s an illustration demonstrating how fuel consumption can vary due to the aforementioned factors. This graphic depicts a study conducted on five sistership vessels throughout April 2024. Despite having similar operational profiles, there were significant discrepancies in average daily fuel consumption.

Navigating Solutions:

- Digital Reporting solution: optimizes your fleet’s fuel efficiency by analyzing data and providing deep insights and best practices. This empowers you to use the most efficient transit routes and practices, enhancing overall operational performance.

- Route Optimization: leverages real-time data on factors such as weather conditions, sea currents, vessel performance capabilities, and traffic patterns to identify the most fuel-efficient routes for the journey.

- Deadweight & Deck space management: Optimize deck space, reduce resistance, enhance performance, and minimize the need for excessive engine power, ultimately reducing fuel consumption.

- Crew Coordination and Familiarization: minimizes disruptions to vessel operations and optimizes fuel usage.

Conclusion:

In addressing fuel efficiency challenges during field transits, it’s clear that optimizing consumption requires a multifaceted approach. OSVs encounter various challenges, including remote operations, weather, and equipment maintenance, while facing complex activities.

Embracing innovation, leveraging data-driven insights, and implementing effective navigation solutions allow the maritime industry to tackle fuel efficiency challenges in offshore field transits with confidence and sustainability.