Fuel consumption is one of the largest operational costs in the offshore industry. In some maritime sectors, such as shipping, fuel costs can climb as high as 46% of total operating expenses [source]. With the growing urgency to improve operational efficiency and reduce environmental impact, ensuring fuel data accuracy and reliability has become a priority. While electronic fuel monitoring systems (EFMS) and sensors have made it easier to track usage, ensuring high-quality, actionable data remains a challenge.

The solution lies in adopting a fully integrated fleet management system that combines real-time data insights with maritime expertise. Such an approach doesn’t just track fuel consumption, it enables a deeper understanding of operations, helping identify discrepancies and inefficiencies at their root.

The Challenges of Accurate Fuel Consumption Data

Accurate fuel consumption data is critical for optimizing operations and meeting sustainability goals. However, achieving reliable insights is fraught with technical limitations, integration complexities, and insufficient oversight. These obstacles highlight the importance of a comprehensive approach addressing technological and human factors.

- Sensor Reliability Issues

Onboard sensors provide invaluable insights but are prone to miscalibration, wear and tear, and occasional hardware malfunctions. These errors can persist unnoticed without regular maintenance and recalibration, compromising data reliability. - Integration Challenges

Combining data from multiple sources, such as sensors, EFMS, and operational logs, often results in inconsistencies and gaps. Differences in data formats, collection frequencies, and communication protocols further complicate efforts to standardize and validate fuel consumption data. - Data Standardization Problems

Disparate data sources frequently use different units, standards, or benchmarks. Without robust data cleaning and standardization processes, insights are often misleading or unusable, hindering the identification of inefficiencies and optimization opportunities. - Failure to Detect and Contextualize Anomalies

Automated systems often fail to detect anomalies that fall outside predefined thresholds. Additionally, these tools lack the contextual understanding to differentiate between a sensor fault and legitimate operational changes, such as high-speed transits due to scheduling demands. - High Implementation Costs and Complexity

Advanced data collection tools can be costly and complex to implement. These challenges discourage full adoption and often result in partial integration or insufficient training, reducing data reliability and trustworthiness. - Overreliance on Technology Without Human Oversight

Automated systems may flag discrepancies, but understanding the root causes requires experienced maritime analysts. Data interpretations are often incomplete or incorrect without sufficient human oversight, limiting actionable insights. - Inadequate Maintenance and Support

Tools that are not properly maintained, updated, or supported degrade in performance over time. This decline further erodes trust in the accuracy and reliability of the data generated.

These challenges reduce operational efficiency and hinder progress toward sustainability goals, including reducing greenhouse gas (GHG) emissions. Overcoming these issues requires a holistic approach that combines advanced technology, expert human oversight, and rigorous maintenance practices.

Why an Integrated Data Collection Approach Matters

To overcome these challenges, a more cohesive strategy is essential—one that integrates multiple data sources into a single platform. Such a solution provides a real-time, holistic view of fuel consumption, allowing operators to make informed decisions based on reliable insights.

Take, for example, Opsealog’s experience in analyzing data from over 1,000 vessels. By benchmarking fuel consumption across sister ships with similar operational profiles, we’ve identified and resolved inefficiencies, such as:

- Variations in routing practices.

- Operational differences due to crew changes.

- Performance issues stemming from hull condition or engine inefficiencies.

This integrated approach ensures that irregularities are flagged early, enabling timely corrective actions.

Learn more about the offshore support vessel onboard fuel monitoring system market in this article.

Real-World Insight: Addressing Data Inconsistencies

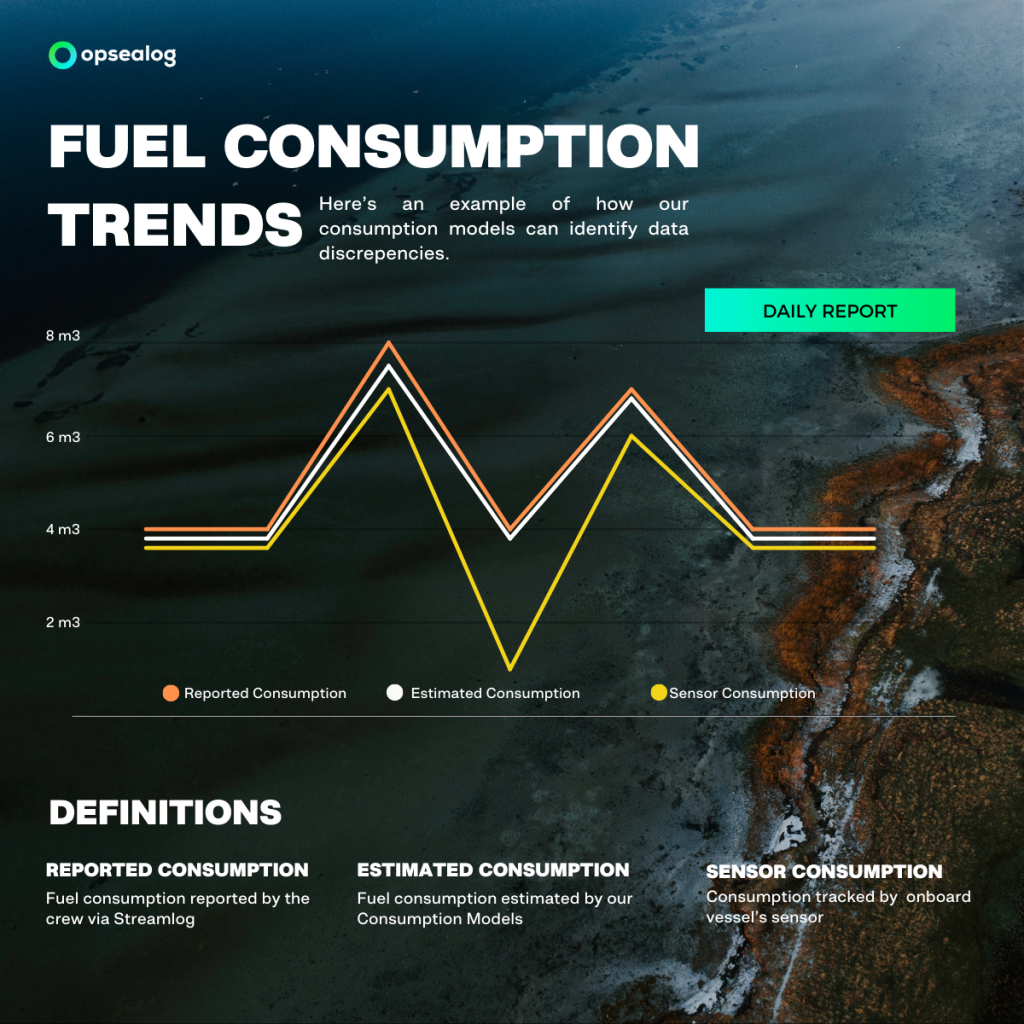

In the following use, Opsealog’s solutions flagged a significant discrepancy between reported, estimated, and sensor-recorded fuel consumption for a client’s vessel. This anomaly, unnoticed by the onboard sensor alone, was identified through a cross-analysis of data from multiple sources.

The Findings

- The onboard sensor was malfunctioning, resulting in unreliable data.

- Manual reporting added further inconsistencies, making assessing the vessel’s true performance difficult.

The Solution

Our team identified the issue by integrating daily vessel reporting (DVR) with advanced consumption models and alerted the client. Following further investigation, we collaborated with the sensor provider to resolve the malfunction and ensure the reliability of future data collection.

The Impact

This proactive approach prevented costly errors and enabled the client to optimize operations based on accurate, trustworthy data. The case underscores the importance of combining advanced technology with diligent data analysis to detect and address issues early.

Without such efforts, anomalies could easily slip under the radar, leading to inefficiencies and unnecessary costs.

The Role of Human Expertise in Data Optimization

While technology is essential for collecting and managing data, human expertise is indispensable for interpretation. Based on model insights highlighting key behaviors’ key influences, experienced maritime analysts play a critical role in translating raw data into actionable intelligence.

At Opsealog, our team of experts doesn’t just highlight discrepancies; they bridge the gap between cutting-edge technology and the client’s deep domain expertise. This holistic approach allows clients to implement targeted solutions that address immediate issues and underlying inefficiencies.

Key Benefits of a Fully Integrated Fleet Management System

By adopting an integrated fleet management solution, operators can achieve:

- Enhanced Transparency: Precise tracking to prevent discrepancies and ensure accountability.

- Real-Time Insights: Immediate access to accurate fuel data for proactive decision-making.

- Benchmarking Capabilities: Compare vessel performance to identify outliers and optimize operations.

- Root Cause Analysis: Quickly pinpoint whether issues are operational, technical, or human.

- Cost Savings: Improved fuel efficiency reduces waste, operational downtime, and overall costs.

These benefits are critical for cost savings, meeting sustainability targets, and improving overall fleet performance.

Moving Beyond Sensors: Toward Data-Driven Fleet Optimization

The future of fleet management lies in turning raw data into actionable intelligence. By integrating data from EFMS, sensors, and operational logs—and combining it with maritime expertise—operators can achieve true data optimization.

However, the immense challenge of aggregating data should not be underestimated. This process requires technical expertise to clean, combine, and refine data for it to become truly actionable. Many companies invest in sensors because they are tangible and reassuring, but its potential remains untapped without the capacity to process the data effectively.

Understanding this gap highlights the importance of specialized solutions like Marinisghts and Streamlog, which simplify complexity and empower clients to focus on their core operational expertise while benefiting from actionable insights.

Learn more about Marinsights and Streamlog.

Final Thoughts

Accurate fuel data isn’t just a metric—it’s the foundation of efficient and sustainable fleet management. By adopting an integrated system that combines advanced tools with expert analysis, operators can ensure data reliability, uncover hidden inefficiencies, and proactively address challenges.

In an industry where every drop counts, trusting your data collection tools and their expertise is essential.

Co-written by Colomban Monnier, Innovation Manager and Marc-Eloi Nicod, Data Scientist at Opsealog.