In the Oil and Gas industry, safety is the number one priority. Safety practices are essential to protecting personnel, preserving the environment, and ensuring operational integrity. With operations spanning exploration, drilling, production, and refining, workers face many hazards, from harsh environments to volatile substances and heavy machinery. Safety concerns fall into two main categories: personnel safety, which prevents accidents and injuries, and asset safety, which minimizes material losses and environmental pollution.

Data has a role to play, helping to identify patterns, recognize risk factors, facilitate experience sharing, and anticipate hazards. By defining objectives clearly, companies can ensure they collect relevant data, making each safety measure more effective.

The Role of Data in Incident Reporting and Tracking

Tracking Lost Time Injury Rate (LTIR) metrics is vital for improving safety across operations. But in the Oil and Gas sector, waiting for incidents before logging data doesn’t capture the whole picture—near misses, incidents narrowly avoiding injury or damage, provide essential indicators of potential risks. Tracking these incidents helps in creating proactive safety practices. However, recording every observation manually can become a heavy burden, and crucial insights may slip through the cracks.

An automated near-miss reporting system simplifies this process, enabling employees to log observations about potentially hazardous situations easily. This creates a valuable source of information that helps QHSE managers detect recurring risks and act proactively. Clear dashboards and accessible metrics reveal safety trends, helping teams prevent serious incidents and strengthen overall safety performance.

Managing Operational Standby: A Practical Example

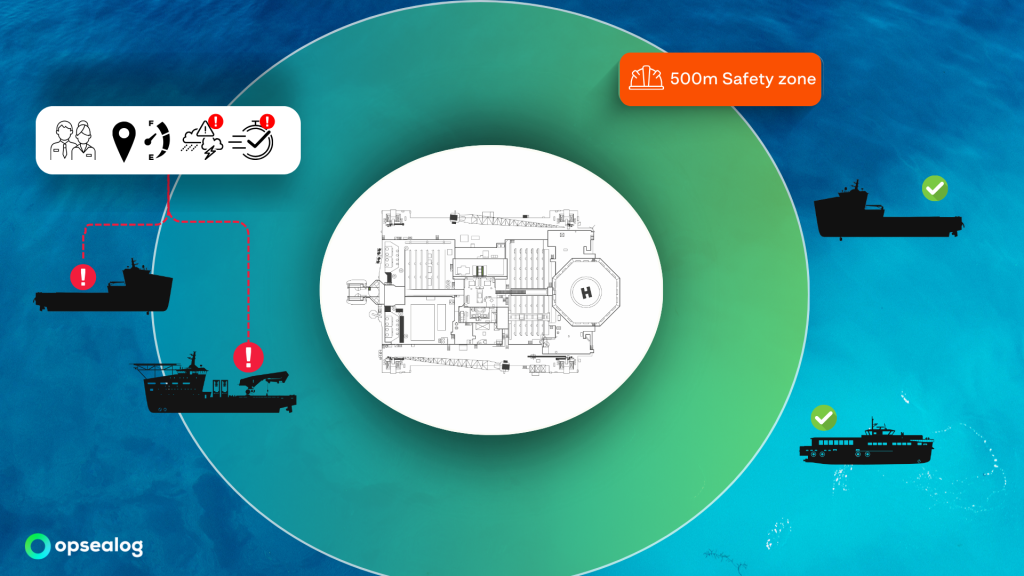

In offshore operations, the 500-meter safety zone around installations protects both assets and personnel. Staying outside this area reduces the risk of unintended contact with installations unless proximity is required for specific tasks. Operating too close without cause heightens safety risks and can lead to regulatory complications.

Seafarers consider various data points for maintaining standby positions—for example, they may position vessels downwind or downstream of the platform, allowing them to drift clear of it in case of engine failure. Yet, certain elements, like crew rotations, crane availability on specific platform sides, or ongoing underwater maintenance, require data only accessible through a centralized system. Data-driven fleet management systems make monitoring vessel positions in real-time easy and flag any vessel entering or lingering near the 500-meter zone, notifying relevant teams to help prevent breaches, uphold operational safety, and avoid risks to nearby structures and personnel.

Monitoring Crew Certification and Training with Data

Data systems can ensure all crew members maintain up-to-date certifications and training, in line with standards set by organizations like IMO and OPITO (Offshore Petroleum Industry Training Organization). By utilizing certification matrices, companies can achieve a balanced crew composition. Furthermore, tracking crew experience helps ensure that skilled personnel can mentor less experienced team members, thus improving safety.

As crew members spend extended periods aboard vessels, fatigue becomes a significant risk factor. Combining data on operational reporting with crew schedules allows companies to develop algorithms that flag when crew members have engaged in intensive activities for too long, prompting timely rotations to mitigate mental fatigue.

Real-Time Risk Assessments

Data plays a critical role in assessing ongoing conditions, such as weather, sea state, or equipment wear, to identify potential hazards proactively. While many operators are trained to conduct risk assessments, simultaneous operations (SIMOPS*) multiply the complexity of these assessments. Pre-processing data points during SIMOPS improves decision-making by reducing the likelihood of oversight and ensuring safety.

For instance, during maintenance operations, multiple activities may occur simultaneously—hull inspections, welding permits, height permits for antenna repairs and equipment installations. Maintaining stability while coordinating these activities requires real-time awareness of who is doing what and where. Without data, teams may rely on outdated paper-based methods that lack the efficiency and clarity necessary for safe operations.

* SIMOPs are situations where two or more operations or activities occur at the same time and place in a facility

Looking Ahead

As we look to the future, data and digitalization will increasingly shape safer offshore operations. The continuous integration of data systems will increase the ability to predict and mitigate risks, ensuring that safety remains at the forefront of offshore activities.

Incorporating data into safety protocols in the offshore industry is a necessity. Organizations can create safer working environments that protect personnel, assets, and the environment by focusing on systematic reporting, crew training, real-time assessments, and operational monitoring.

Want to learn more about other key metrics: https://opsealog.com/5-keymetrics-that-drive-fleet-optimization-and-lower-operational-costs/